KION informs about innovations in logistics and trends

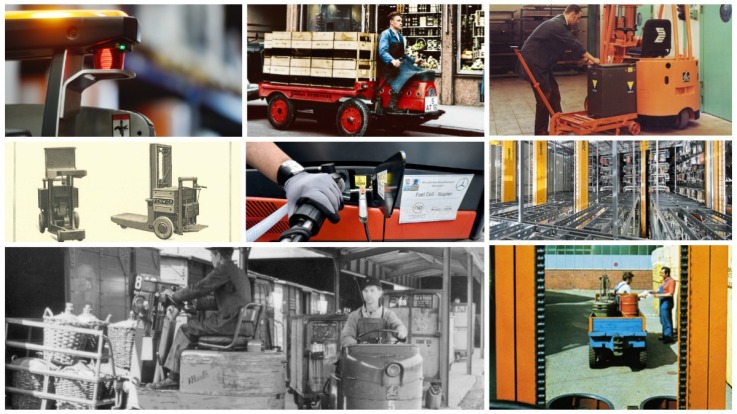

We are driving forward innovation in logistics and the material handling market. The KION Group is one of the technological leaders in the industry and is committed to Intralogistics 4.0. We have roughly 1,700 researchers and developers [as at 2020] around the world who are dedicated to the task of increasing the impact and speed of development of new technologies, products, structures and processes, and working tirelessly to design innovative solutions. On average, we invested almost 3% of our turnover in research and development between 2014 and 2020, primarily in the following fields: new energy , automation, and digitalization – in particular in the field of connectivity.

AI-Assisted Energy Management for Electric Forklift Truck Fleets

A good example of innovation that combines new energy solutions, digitalization, and connectivity is our collaboration with ifesca. We entered this strategic partnership with software developer ifesca GmbH in order to improve our customers’ peak power management. Together, we are working on an AI-assisted energy management platform for electric forklift truck fleets. Artificial intelligence (AI) allows for energy to be used more efficiently in warehouses. With the accurate forecast results from the platform, our customers can optimize the planning of charging times for their industrial truck fleets, avoid charging peaks, and therefore significantly reduce their energy costs. The platform can also be easily and flexibly integrated into existing energy management systems via open interfaces. This provides further benefits for customers, both in regard to savings and in terms of achieving their own sustainability goals .

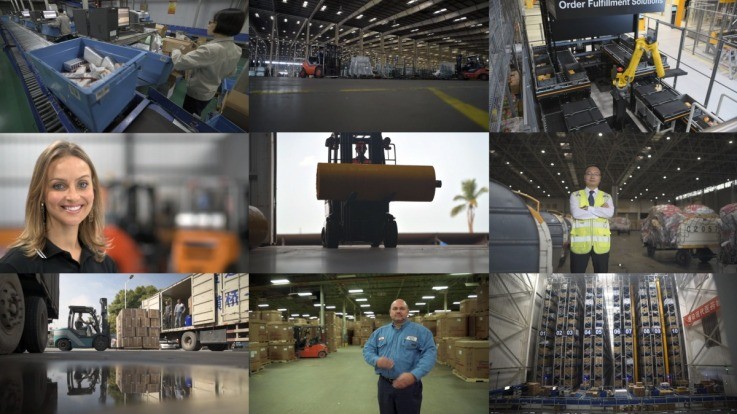

KION Offers Creative Solutions for Intralogistics 4.0 and Innovative Products for the World of Tomorrow

In addition to cost-saving energy management, we are also addressing the issues of high population density in cities and the growing demand for e-commerce products . In order to meet the current need for super-fast deliveries (same-day deliveries), new solutions are required. This is where KION’s concept of micro-fulfillment comes in, which involves small warehouses in city centers as well as networked and automated industrial trucks. KION is also focusing on the “ last mile ” – i.e. the transportation of a package to its final destination – which is the most expensive link in the logistics chain. While the production time in the manufacture of a product is precisely calculated and optimized, and processes in a warehouse are often automated, the last mile still involves a considerable amount of manual labor. In order help parcel delivery companies, our subsidiary brand Dematic is developing “ PackMyRide ” – an automated system that packs the truck ready for the driver. At the distribution center, the robot arm removes packages from the conveyor belt, the system analyzes the size and weight, and then the truck’s mobile racking units are loaded in an optimal and space-saving manner. This not only reduces the physical exertion on the part of the driver, but also significantly reduces the time spent loading the trucks. Dematic tested the pilot system together with its project partner DPD , an international courier, express, and parcel service provider. This is how we intend to meet the current requirements of Intralogistics 4.0 and be a pioneer of innovative solutions.

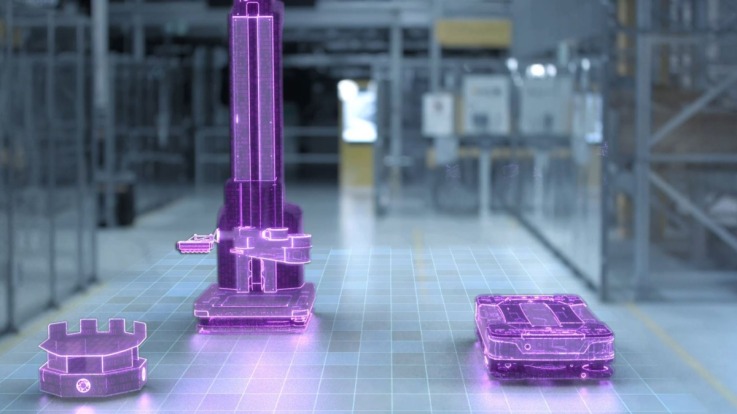

Innovation in Logistics: Research Communities and KION

Aside from partnerships with companies such as DPD , we are also working with research institutes, universities and, of course, our customers themselves. This ensures that our innovations are always tailored to the market and the latest technological developments. Another example of this is LoadRunner? – a new generation of autonomous transport vehicles that the KION Group and Fraunhofer IML have developed together. We licensed Fraunhofer’s AI-assisted driverless transport vehicles and brought these highly dynamic vehicles to market maturity as part of our joint “ Enterprise Lab .”

Safety Is Always Top Priority

KION is also conducting research into health and safety in the workplace, as the wellbeing of our staff and customers is of paramount importance. We are involved in a great deal of R&D when it comes to personal safety on-site – be it driverless transport systems that automatically reduce their travel speed, special safety vests that warn the wearer of approaching traffic, or control systems that ensure items are positioned safely in high rack warehouses. We are also working on fire protection methods for automated warehouses and installing solutions for preventing fires by reducing the amount of oxygen in warehouses.

_image_737x414.jpg)

/mpm_smurfit_kappa_keyvisual_image_737x414.jpg)